Artificial Intelligence in the Packaging Industry in 2025: Revolutionising Tomorrow’s Packaging

COMMENT L’IA RÉVOLUTIONNE LE DÉVELOPPEMENT PACKAGING – TABLE RONDE SALON C!PRINT 2025, LYON

Over recent years, the adoption of Artificial Intelligence has gained significant ground across multiple sectors. In the packaging industry, this evolution is accelerating to address economic, environmental, and cultural challenges. What are the concrete benefits of AI for packaging in 2025? Which strategies should be prioritised to remain competitive and enhance your environmental footprint?

In this article, we explore in detail the opportunities and trends emerging from AI in the packaging industry, featuring concrete examples and insights from recognised professionals.

- 1. Context and Challenges of Packaging in 2025

- 2. L'IA chez les Grands Acteurs de l'Emballage

- 2. Main Application Areas of AI in Packaging

- 3. Design et personnalisation à l'ère de l’IA

- 4. Sustainability and Eco-Design: AI as a Lever for Innovation

- 5. Some Testimonials on New Trends in Packaging

- 6. A Closer Look at the Challenges: Legislation, Costs and Collaboration

- 7. Comparison: Traditional Packaging vs. AI-Driven Packaging

- 9. Conclusion

1. Context and Challenges of Packaging in 2025

The French packaging market is a dynamic sector, with a production value of €18.3 billion in 2019. Packaging production in France is dominated by plastic (38%), followed by paper and cardboard (29%).

Recent market studies indicate a rapid rise in AI’s role within packaging. According to a GlobeNewswirereport, the global market for AI in packaging is expected to exceed $23 billion by 2034. In France, growth is driven by the rising demand for sustainable solutions, automation, and the advent of smart packaging.

At the same time, the industry must contend with stricter regulatory requirements, an increasingly environmentally conscious consumer, and the need to differentiate in a competitive market. Consequently, AI emerges as a transformative lever, enabling:

- Optimisation of production costs.

- Reduction of the ecological footprint (waste, carbon emissions).

- Improvement in product quality and safety.

- The personnalisation and the creation of new customer experiences.

le marché mondial de l’IA pour l’emballage devrait franchir le seuil des 23 milliards de dollars à l’horizon 2034.

2. AI Among the Major Players in Packaging

L’Oréal employs AI for product personalisation and R&D optimisation.

The company notably acquired Modiface, a firm specialising in virtual makeup trials that uses computer vision and AI to deliver a tailored customer experience.

Nestlé explore l’IA pour optimiser ses processus de production et améliorer la durabilité de ses emballages. L’entreprise a investi dans Timeplast, une startup qui développe des technologies pour minimiser l’impact environnemental du plastique mal recyclé, en veillant à la compatibilité avec les systèmes de recyclage existants.

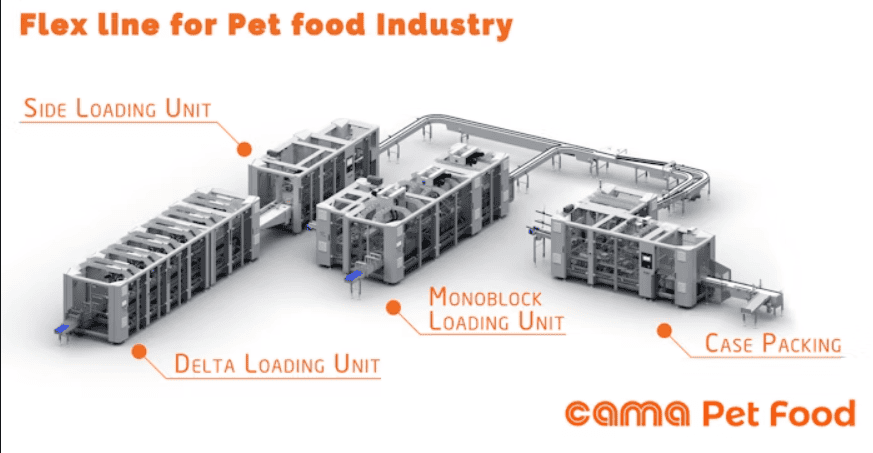

Moreover, Nestlé utilises AI to automise its packaging operations. For example, Nestlé Purina deploys robotic systems in its Wroclaw facility in Poland for tasks such as grouping and packing cans into cartons.

Additionally, Nestlé employs AI to develop packaging concepts for the food sector, notably by utilising “cryovacs” to weigh and automatically seal products in airtight packaging. AI also improves the precision of filling processes, as exemplified by Nestlé’s partner Marzetti.

2. Main Application Areas of AI in Packaging

Advanced Automation

Automated production lines can benefit from AI to manage quality control, predictive maintenance, and logistics flows. With the aid of computer vision, the detection of anomalies or defects is faster and more reliable than manual inspection.

Optimisation of the Supply Chain

AI facilitates the traceability of packaging—from the sourcing of raw materials to final distribution. Predictive algorithms ensure better stock management and minimise waste. According to McKinsey & Company, such optimisation also accelerates time-to-market.

Packaging Design and R&D

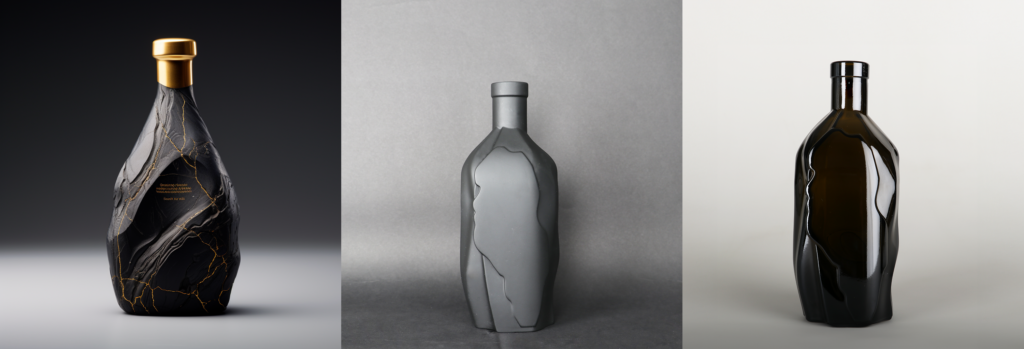

Generative AI tools (text-to-image, image-to-image, image-to-3D, image-to-video…) enable the rapid generation of innovative packaging concepts. Virtual testing validates aspects such as strength, shape, and durability without the need for numerous physical prototypes. This translates into significant time-savings alongside reduced costs.

Passionate about the future of packaging design in the age of artificial intelligence, Ludovic—the founder of Studio Blackthorns—regularly delves into this theme on his programme The Bottlefield Show. Across several episodes, he explores the fascinating prospects that generative AI offers in transforming contemporary packaging design. Studio Blackthorns, approfondit régulièrement cette thématique dans son émission The Bottlefield Show. À travers plusieurs épisodes, il y explore les perspectives fascinantes qu’offre l’IA générative dans la transformation du packaging design contemporain.

The French and European packaging markets are booming, driven by innovation and the demand for sustainable solutions. AI plays a crucial role in this evolution, enabling companies to meet the growing challenges of personalisation, automation, and eco-design. — Ludovic Mornand, Studio Blackthorns

3. Design and Personalisation in the Age of AI

Creation of Distinctive Packaging

Trends observed in designers’ testimonials confirm a shift towards an aesthetic deeply embedded in brand culture rather than fleeting trends. AI supports the generation of unique patterns, bespoke colour palettes, and fresh visuals, resulting in designs that are both impactful and aligned with the tastes of each customer segment.

Dans une démarche novatrice, le Studio Blackthorns a brillamment orchestré la renaissance d’une marque emblématique en conjuguant tradition et modernité. La bière belge Gertrude, dont l’identité visuelle s’articulait autour d’une représentation médiévale de la sainte éponyme, s’est métamorphosée grâce à l’intelligence artificielle de Replicate. Cette transformation audacieuse de l’étiquette historique illustre parfaitement comment les technologies génératives peuvent insuffler une nouvelle jeunesse aux marques séculaires, tout en préservant leur authenticité. Une belle démonstration de l’art d’ancrer l’héritage brassicole belge dans l’ère numérique de 2025.

Illustration of Gertrude Beers – Brand Redesign by Studio Blackthorns

Connected and Hyper-Personalised Packaging

AI paves the way for major innovations in packaging design. It notably enables the creation of smart packaging that interacts with consumers. Integrated sensors and chips can provide product information, track traceability, and display expiry dates—enhancing the overall customer experience.

Moreover, 3D printing combined with AI allows for the production of packaging with complex, customisable shapes, opening up new possibilities in design and functionality. AI assists designers in overcoming the challenges related to developing packaging prototypes, particularly for cosmetic products that feature intricate geometries and transparency.

Thus, artificial intelligence enables hyper-personalisation:

– Limited editions for specific events.

–3D printing of customisable, complex forms.

– Label adaptation based on user preferences (for example, via a QR code that displays targeted information).

The Cultural Dimension and the Spotlight

As design professionals note, packaging can serve as a powerful cultural medium. Brands are increasingly incorporating cultural elements, bespoke typefaces, and colour palettes inspired by regional trends. AI can analyse vast visual databases to suggest creative directions influenced by pop culture, art movements, or even local traditions.

The recent ‘Go Wild’ advertising campaign by Zubrowska exemplifies this creative audacity. The vodka brand transports its audience into an unbridled, surreal realm where the boundaries of imagination vanish, giving way to a world where the impossible becomes reality. It is an intoxicating invitation to escapism and excess.

4. Sustainability and Eco-Design: AI as a Lever for Innovation

Optimised Material Selection

AI algorithms help assess the environmental impact of various materials by considering factors such as life cycle, recyclability, and biodegradability. This approach encourages a proactive and transparent form of eco-design.

Soluble and Reusable Packaging

Narratives shared by certain designers confirm the onset of soluble packaging (for example, in the cosmetic or food sectors). In parallel, reusable solutions—such as boxes or containers designed to be returned and re-used—are emerging. AI further supports these solutions by managing collection flows and optimising logistical processes.

Reduction of Carbon Footprint

AI-driven simulations enable the adjustment of packaging shape and density, reducing the quantity of raw materials used while maintaining the required durability. This leads to a marked decrease in resource consumption and transport-related emissions.

5. Some Testimonials on New Trends in Packaging

Beyond the numbers, various experts outline what the future of packaging in 2025 might hold:

- Chris Wilson (Stckmn): He underlines the importance of balancing premium finishes with ecological requirements. Digital experiences (such as integrated QR codes and immersive storytelling) can replace certain costly and polluting embellishments.

- Fred Hart (Independent): He cautions against the banalisation of the “Gen Z” style—which is too quickly replicated. A brand should leverage AI to deepen its own identity rather than simply mirroring standardised codes.

- Andy Kurts (Buttermilk Creative): He addresses the challenge of scaling sustainability: how does one generalise the use of recyclable or compostable materials while still catering to economic realities?

- Ludovic Mornand (Studio Blackthorns): With a considered and measured approach, Ludovic stresses that artificial intelligence must be seen as a tool in service of creativity—not as an end in itself. In his day-to-day practice of packaging design, he harnesses the potential of generative technologies to enrich his creative process and expand exploratory possibilities. His workflow seamlessly integrates cutting-edge tools such as Magnific, innovative Photoshop features, image upscaling, and vector illustration generation—transforming each iteration into a wellspring of inspiration.

Various designers also highlight the rise of refill systems and the potential of AI tools to assist consumers in recycling more effectively.

6. A Closer Look at the Challenges: Legislation, Costs and Collaboration

Evolving Legislation

Across the globe, regulations are tightening to reduce single-use plastics and encourage recyclability. AI can help anticipate these changes by enabling companies to swiftly adjust their formulations or packaging designs. This, however, implies:

- Maintaining constant legal vigilance.

- Precisely calculating the cost–sustainability impact.

Cost Management

Although AI accelerates processes, the deployment of sophisticated tools can represent a significant initial investment. Smaller organisations may be tempted to delay such investments; however, an increasing number of cloud-based solutions and “as-a-service” platforms are making AI more affordable.

Collaboration Within the Ecosystem

The success of these innovative approaches (e.g. soluble packaging or return loops) relies on close collaboration among manufacturers, distributors, and recyclers. Coordinating the management of flows and returns often requires large-scale data analysis – a task where AI is invaluable in organising and optimising the complete ecosystem.

7. Comparison: Traditional Packaging vs. AI-Driven Packaging

| Aspect | Traditional Packaging | AI-Driven Packaging |

| Operational Efficiency | Labour-intensive manual processes | Automated and streamlined processes |

| Design and Labelling | Static designs, manual labelling | Customised designs, AI-driven label generation |

| Customer Experience | Generic packaging for the mass market | Hyper-personalisation – tailored packaging and interactive experiences |

| Sustainability | Limited eco-friendly options, high waste production | Eco-friendly sourcing, waste reduction, recyclability analysis, reduced carbon footprint |

| Quality Control | Manual inspection, risk of errors | Automated defect detection via industrial vision, high accuracy |

| Cost Efficiency | Higher labour costs, potential inefficiencies | Cost savings via automation, waste reduction, optimised stock management |

| Data Analysis | Limited insights, manual data collection | Predictive analysis, real-time data tracking, demand forecasting, enhanced decision-making capabilities |

| Supply Chain Optimisation | Manual processes, potential bottlenecks | Optimised shipping routes, reduced transport costs, real-time stock management |

| Customer Support | Traditional telephone support, limited availability | 24/7 AI-powered support with chatbots for instant assistance |

| Innovation | Gradual improvements, slower market adaptation | Rapid innovation cycles, quicker response to market demands, AI-driven product and packaging development |

| Competitive Advantage | Limited brand differentiation, slower time-to-market | Enhanced brand differentiation, faster product launches, increased market agility |

9. Conclusion

L’Intelligence Artificielle apparaît comme un catalyseur incontournable pour repenser l’industrie de l’emballage en 2025. De la personnalisation poussée à l’optimisation éco-responsable, ses applications touchent tous les maillons de la chaîne de valeur, des fabricants aux consommateurs.

However, embracing AI requires a strategic vision and an expanded culture of innovation. It is no longer solely about reducing costs, but about reinventing the models of design, production, and distribution.

Sources

- McKinsey & Company – Generative AI: The packaging and paper industry’s next frontier

- GlobeNewswire – Global AI in Packaging Market Projection

- La France, troisième producteur européen d’emballage – Insee Focus

- Nestle Purina’s ‘Most Modern’ Packaging Operation

- Comment l’intelligence artificielle révolutionne les emballages alimentaires écoresponsables ?

- Comment l’IA révolutionne le design d’emballage

- L’Oréal Propulse sa R&D Grâce à l’Intelligence Artificielle

- Nestlé explores alternative packaging technologies with startup investment – Food Dive

- Nestle Purina’s ‘Most Modern’ Packaging Operation

- AI and Technology in Food Manufacturing: How Nestle and Others Stay on Top – Kitameraki

(For more inspiring content, also check out our blog and our page dedicated to our brand identity projects.)

FAQ: Your Questions on AI and Packaging in 2025